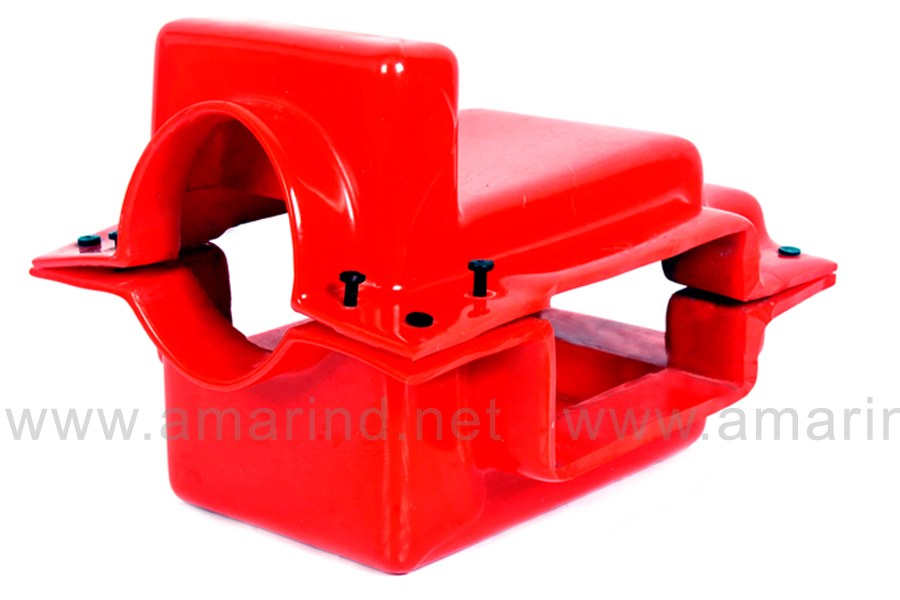

Insulating the bus bar & Switchgear joints is very unmanageable and exceptional job owing to a very exceptional job owing to a very complex and varied profile of the joints in the layouts that are of much customized nature. Because of this majority of the joints are left open without insulations.

In many advanced countries and few MNCs have made it mandatory to use flexible shrouds made of PVC Plastisols for insulation of joints. These electrical insulation shrouds are easily mountable, replaceable and serviceable but also possess better heat resistant and electrical properties and are very durable. These are also resistance to UV exposure ageing.

Features

- Suitable for insulating bus bar joints. (Tee, elbow, etc.)

- Provides significant reduction in air clearances

- Excellent thermal & electrical properties

- Good for indoor & outdoor applications

Technical Data

| Sr. No. | Properties | Value | Standard |

|---|---|---|---|

| Physical | |||

| 1 | Tensile Strength | 11 N/mm² (MPA)(min.) | ASTM D 412-06a |

| 2 | Ultimate Elongation | 250% (Min.) | ASTM D 412-06a |

| 3 | Longitudinal Change | 0.5 % (Max.) | ASTM D2671 |

| 4 | Hardness | 60 ± 10 Shore D | ASTM D2240 |

| 5 | Water Absorption | 0.5 % (max.) | ASTM D570 |

| Thermal | |||

| 6 | Accelerated Ageing for 110°C for 300 Hrs | ||

| Tensile Strength | 9 N/mm2 (Mpa) (min.) | ASTM D 412-06a | |

| Ultimate Elongation | 150 % (Min.) | ASTM D 412-06a | |

| 7 | Heat Shock (120oC for 4 Hrs.) | No Cracking or flowing | ESI 09-11 |

| 8 | Continuous Temperature limit | -40°C to + 110°C | IEC 216 |

| Electrical | |||

| 9 | Dielectric Strength | 6 to 12 KV/mm. | ASTM D149 |

| 10 | Volume Resistivity | 1012 Ohm.cm | ASTM D257 |

| Flammability | |||

| 11 | Flammability | Pass | UL-94 (V-0) |